Go Green and recover your compressors energyUsing a relatively inexpensive conversion process your modern Atlas Copco ZR compressor can be converted to supply 90'c water for various uses around your plant., effectivly using your energy twice.

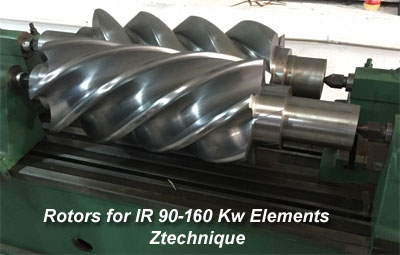

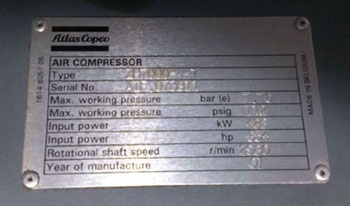

This isn't a new concept , the energy recovery concept for ZR compressors has been around a long time since ZR3,4,5,6 machines where established on the market many years hence. What has made conversion easier is the new design of the ZR110 to ZR900 for example allowing much lower cost conversion to Energy Recovery. from as low as a few thousand pounds conversion to your modern ZR equipment you could be easily recovering wasted energy..

As a result, the total energy recovered as hot water amounts up to 80-105% of the electrical input energy, depending on the individual site conditions. In most industrial conditions it will be 90 to 95%. This feature sets the ZR oil-free screw compressor with energy recovery apart from any other compressor technology

The heat gathered can be easily pushed through a plate heat exchanger with some other simple additions to provide how water for as an example at between 70 to 90'c

Showers

Space Heating

Steam Boilers

Process Water

Heat Driven Chillers

etc

|

Heatback Energy Recovery productsCompact design

For use with oil Injected screw compressors from 7.5 to 110 kW

Max possible amount of heat 6.1 to 88.8 kW

Max operating temp of water 95'c

Max water pressure 10 bar

Oil temperature regulated water valve

Can be used with various manufacturers compressors

No external energy source required

Buy on line today

See the Heatback Products and buy online now

|

What's in our Heat Recovery External Package for Z compressorsTo extract the useful heat from the water produced by the compressor you will need an external package designed with optimising your particular situation.

Our External Heat Recovery Package consists of

- Variable speed water pump

- Electronic controlled 3 way by-pass valve

- Control Panel microprocessor with graphical display

- Pre-mounted electrical cubicle

- Single point of electrical connection (380-500V 50/60 hz

- Stainless steel gasketted plate heat exchanger(s)

- Pressure relief valve

- Pressure expansion vessel

- Automatic de-aeration valve |

| |

Consider the Heat Lost from Oil Flooded CompressorsOver 90% of the electrical input to a compressor is lost as heat. Companies can reduce their

consumption of heating fuel by recovering waste heat from air and water cooled compressors

and save money. The Carbon Trust

The choice of system depends on the type of compressor, its cooling system and how the recovered heat will be used. The following diagrams show the type of heat recovery possible from compressors and the technology needed to use that heat.Temperatures of up to 80ºC can be reached in the discharge ducting.

The Carbon Trust PDF on Heat Recovery |

| |

Where do we go from here ?Contact Air Hire and we can carry out a FREE survey of your compressed air system and recommend a suitable solution combined with energy saving calculations for the energy recovery possibilities for your plant.

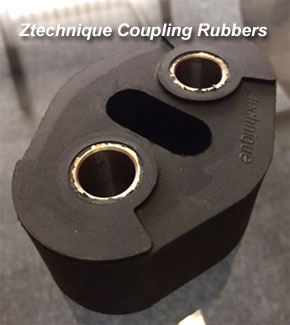

What's more we manufacture the equipment and ZR conversion kits in house so we are considerably less expensive than the OEM's.

With examples already operating around the UK this is a great time to recover energy and be a greener business.

Please click here to use our email service or call 00 44 1744 733211 and ask for Energy Recovery solutions

|

Airtec Filtration & AirHire.co.uk Oil Free & Oil Flooded Compressor Spares